Y JD series Star Unloader

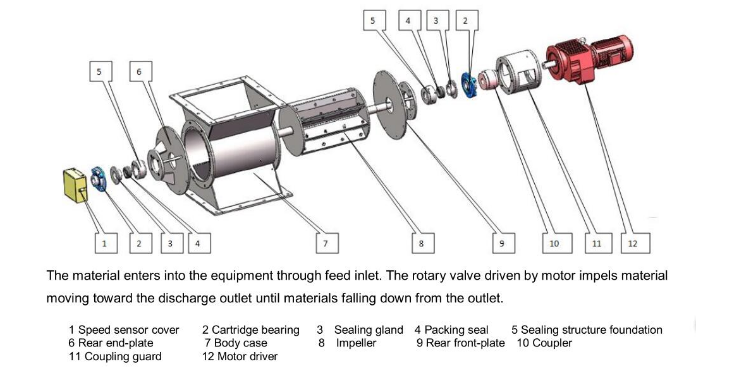

YJD-A/B series unloading device, also known as electric ash unloading valve and electric lock valve, consists of three parts: motor, tooth difference planetary reducer (X) or pinwheel cycloid reducer (Z) and rotary unloader. There are two series and 60 specifications

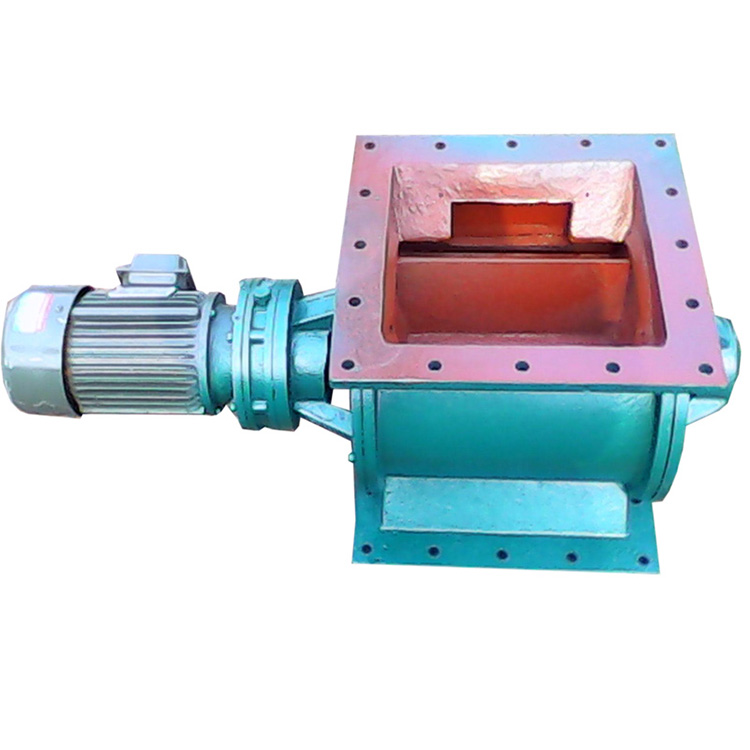

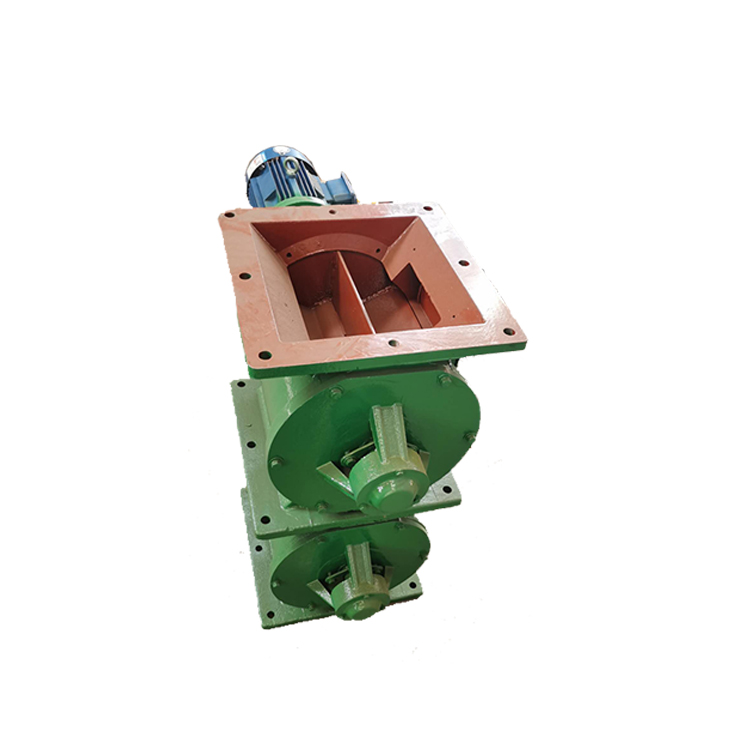

The square flanges of import and export are type A, and the circular flanges are type B

The device is a dust removal equipment, the main equipment for conveying, discharging ash, locking air and other equipment feeding. It is suitable for powder and granular materials. Installation size is consistent with all kinds of dust collectors, which is widely used in environmental protection, mining, metallurgy, chemical industry, grain, chemical and other industrial sectors

Special motors, such as explosion-proof, frequency modulation, speed regulation and marine motors, can be configured according to needs of users in order to meet users'special requirements. The material can also be processed according to the needs of users, such as high humidity resistance, corrosion resistance, stainless steel, flexible blades, explosion-proof impellers, etc

Technical parameters of A/B-X/Z YJD unloader:

|

Model Name Data |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

|

|

Unloader L/r |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

26 |

30 |

|

|

Unloader m³/h |

4.08 |

8.16 |

12.24 |

16.32 |

20.4 |

24.48 |

28.56 |

36.64 |

36.72 |

40.8 |

50.64 |

61.2 |

|

|

Inner diameter mm |

150 |

180 |

200 |

220 |

240 |

260 |

280 |

300 |

320 |

340 |

400 |

440 |

|

|

r/min |

Type Z |

25-40(standard speed:34r/min) |

|||||||||||

|

Working temperature °C |

T ≤80°C T ≤200°C |

||||||||||||

|

Materiel |

Powdery, granular |

||||||||||||

|

Electric machinery |

Model |

Y801 |

Y802-4 |

Y90S-4 |

Y90L-4 |

Y100L1-4 |

Y100L2-4 |

||||||

|

KW |

0.55 |

0.75 |

1.1 |

1.5 |

2.2 |

3 |

|||||||

|

r/min |

1390 |

1400 |

1430 |

||||||||||

|

Weight kg |

53 |

71 |

86 |

101 |

121 |

141 |

161 |

181 |

191 |

221 |

251 |

301 |

|

Y JD series Star Unloader

Product Description

Airlock valve,also named discharge valve,star discharger,cindervalve,is an important equipment for pneumatic conveying system and dust removal system.

It is mainly used to discharge the material continuously from the tripper and dust collector,and make sure the inner pressure not exposed to atmosphere pressure evironment.

The airlock valve is made of gear motor,sealing element,impellers and rotor housing on which many rotating blades are set.It is capable of discharging powder,small particles,flaky or fibre continuously by the differential pressure of material.Now it has been widely used in chemical,pharmacy,drying,grains,cement,environmental protection and power industry etc.

Working Principle:

Material falls onto the blades and rotates with the blades to the outlet under the airlock valve.Material can be discharged continuously.

In pneumatic conveying system,the airlock valve can lock the air and supply material continuously. The low speed of the rotor and tiny space can prevent the airflow from reverse flow,and ensure a stable air pressure and regular discharge of the material.The arilock valve acts as the material discharger in the material collecting system.