What is a Baghouse Type Dust Collector

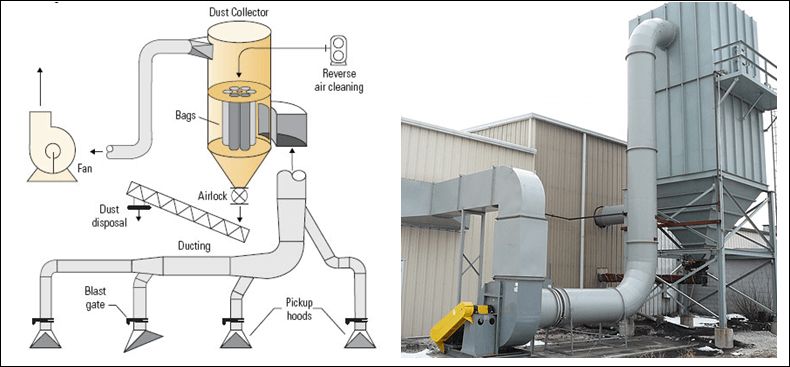

Most baghouses dust collector system have a filter clean system of one type or another. There are three common types of filter cleaning systems.

- Shaker System: This is the most basic filter cleaning system and typically uses a motor to shake the dust particulate off the outside of the bags.

- Reverse-Flow: This utilizes a fan that continuously moves around and blows air into the center of a bag, which forces the dust off the outside of the bag.

- Pulse Jet Filter: This method shoots a blast of compressed air down the center of a bag and forcibly blasts the dust off the outside of the bag.

Production Description

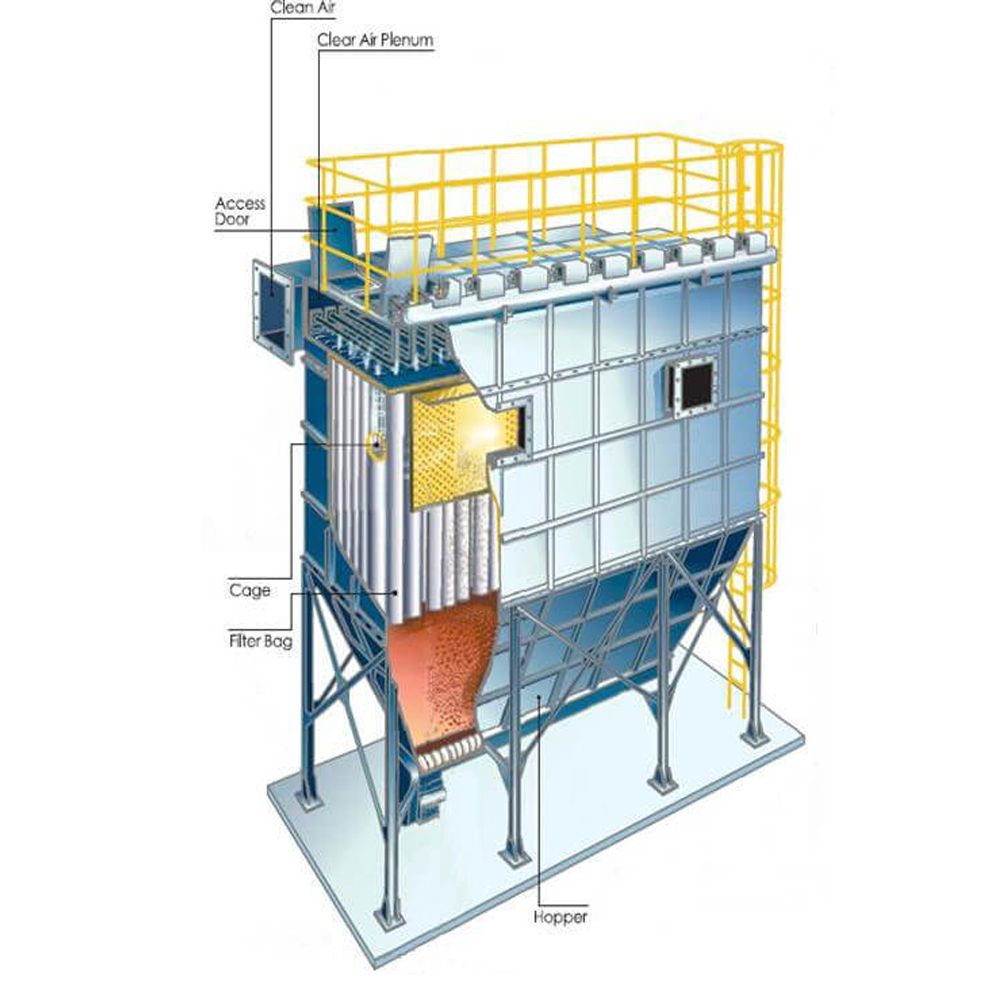

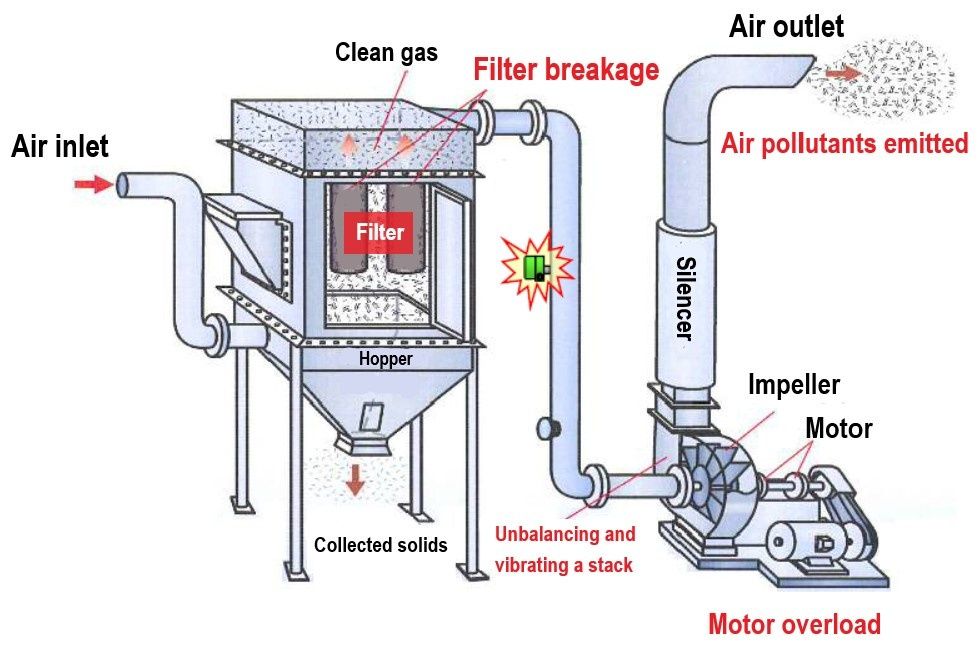

Baghouse dust collectors use long, cylindrical bags (or tubes) made of fabric to filter dust particles out of the airstream. The dirty air enters the dust collector and is directed to the filters of the baghouse. Dirty air passes through the bags where the dust particulate is collected outside the filter while clean air passes through the filter. The clean air is released into the environment or recirculated back into the facility.

Most baghouses have a filter clean system of one type or another. There are three common types of filter cleaning systems.

- Shaker System: This is the most basic filter cleaning system and typically uses a motor to shake the dust particulate off the outside of the bags

- Reverse-Flow: This utilizes a fan that continuously moves around and blows air into the center of a bag, which forces the dust off the outside of the bag.

- Pulse Jet Filter: This method shoots a blast of compressed air down the center of a bag and forcibly blasts the dust off the outside of the bag.

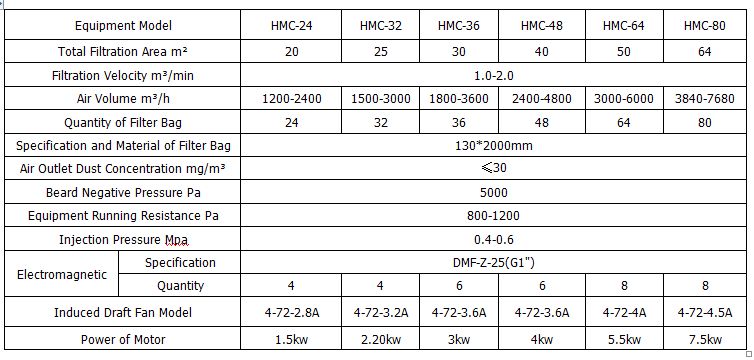

Production Parameter

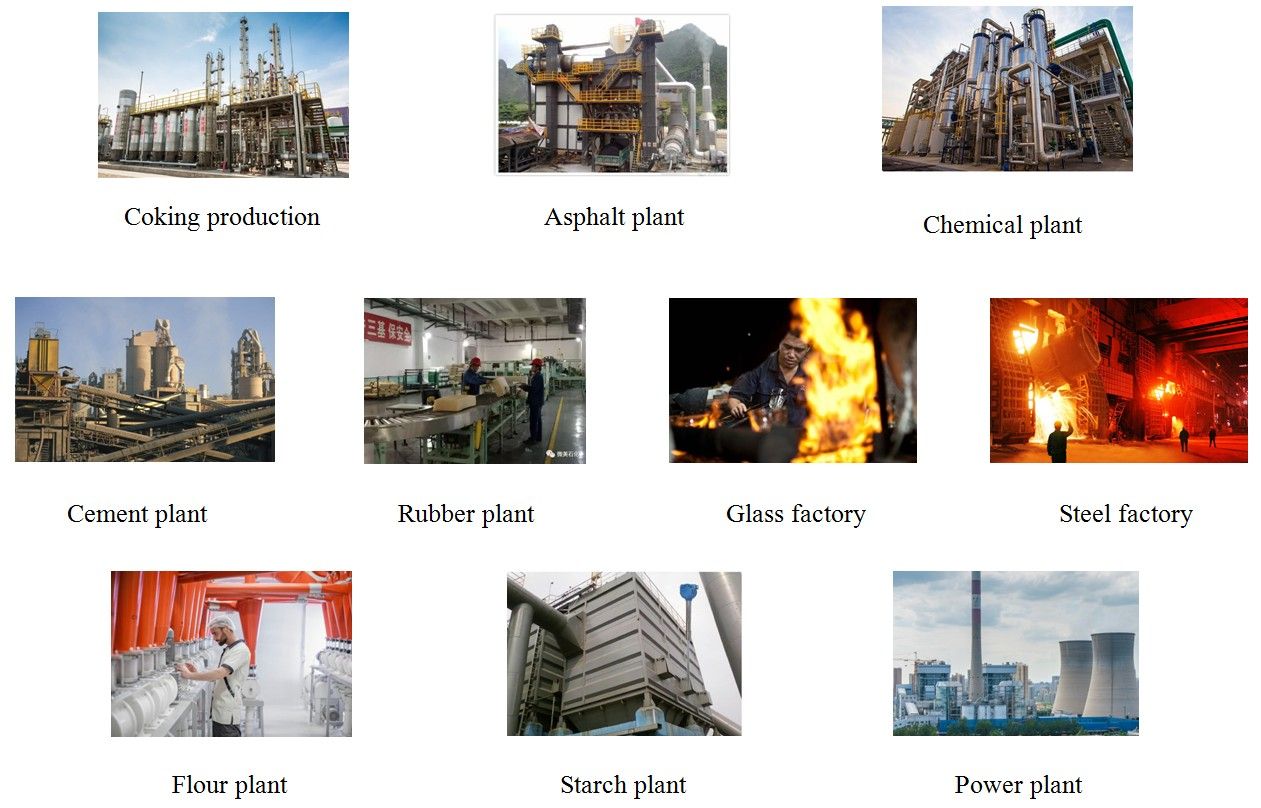

MainApplication

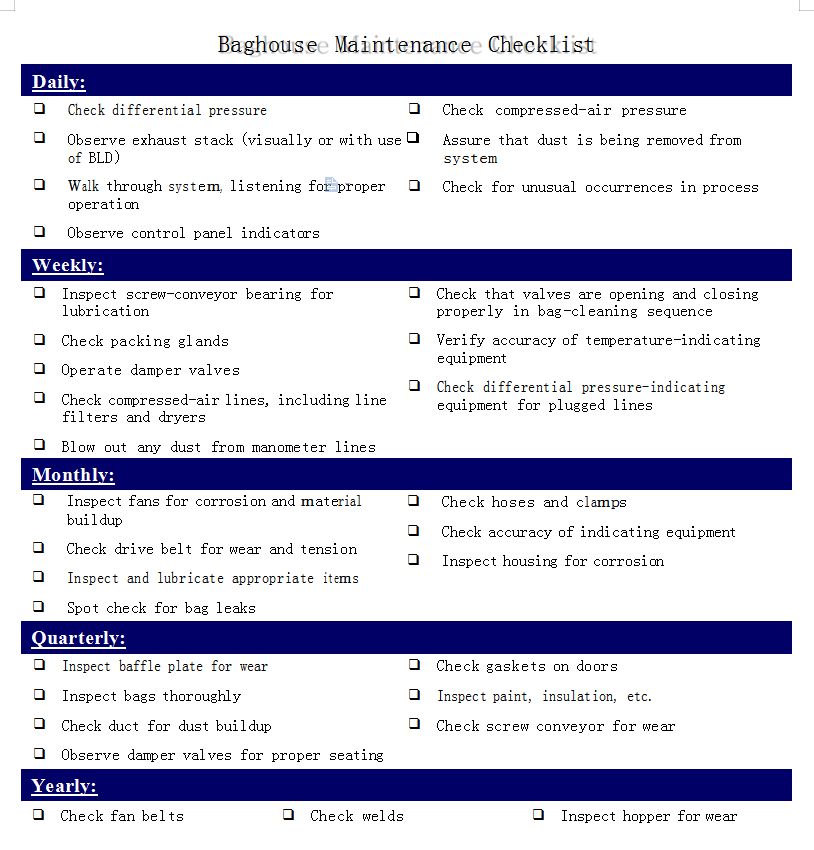

Dust Collector Maintance

1.Check that the DP meter is working properly. .

2 Empty the hopper. .

3 Use the right parts. .

4 Program clean Settings properly. .

Make sure the bag leak detection system is set up correctly

Packing &Shipping

Filter Bag of Dust Collector

The filter bag is the key component to determine the dust removal efficiency and working temperature of the bag dust collector,and the cost of replacing the filter bag is the main maintenance cost of the bag dust collector.thereforce,the working life of the filter bag is related to the operation state and cost of the dust collector,so it is particularly important to select the appropriate dust collector filter material and design the reasonable structure.

Working Principel

Its working principle is: filter slurry (suspension) with a filter bag into the container, through the filter bag for filtration. The diameter of the filter bag is larger than the cage frame, and the filter bag is attached to the cage when the filter is pressed. The filter bag forms a cake bag on the surface of the filter bag. After filtering the filtrate on the surface of the filter bag, the filter cloth of the filter bag is filtered. After filtering, the filter residue of the filter bag is filtered in the filter layer of the filter bag.

Company Profile

Botou Xintian Environmental Protection Equipment Co., Ltd is a professional dust removal equipment and dust removal accessories manufacturer in collection of research and development, design, equipment manufacturing, field installation, and commissioning Our company mainly produces: electric dust collector, high voltage electrostatic dust collector, rotary umbrella type high efficiency electrostatic dust collector, collecting high voltage electrostatic dust collector, tube pole type electrostatic dust collector, wide spacing electrostatic dust collector, pulse bag dust collector, long bag off-line pulse dust collector, high voltage off-line pulse bag dust collector, micro shock flat bag dust collector, rotary back blowing dust collector, bag type back blowing dust collector, single machine dust collector unit, single bag dust collector, single bag dust removal equipment, cyclone dust collector, coarse powder separator, wet vertical kiln dust collector for Industrial, desulphurization dust collector , various types of electromagnetic pulse valve, YJD series (discharge valve), horizontal reducer, vertical reducer, planet cycloid pin wheel reducer, a variety of dust removal cloth bag series, a variety of bag cage series, pulse controller, cylinder, electric control cabinet and other dust collector accessories products, and we can also do non-standard design, modification and installation according to the requirements of users.