Top Suppliers Multi Cyclone Dust Collector Working Principle - Cyclone Dust Collector – Xintian

Top Suppliers Multi Cyclone Dust Collector Working Principle - Cyclone Dust Collector – Xintian Detail:

Under ordinary operating conditions, the centrifugal force acting on the particles is 5 ~ 2500 times that of gravity, so the efficiency of cyclone dust collector is significantly higher than that of gravity settling chamber. Based on this principle, a cyclone dust removal device with dust removal efficiency of more than 90 percent has been successfully studied. Among the mechanical dust removers, the cyclone dust remover is the most efficient one. It is suitable for the removal of non-viscous and non-fibrous dust, mostly used to remove more than 5μm of particles, parallel multi-tube cyclone device for 3μm of particles also has 80 ~ 85% of the dust removal efficiency. The cyclone dust collector is made of special metal or ceramic materials with high temperature resistance, abrasion resistance and corrosion resistance. It can be operated under the conditions of temperature up to 1000℃ and pressure up to 500×105Pa. In terms of technology and economy, the pressure loss control range of cyclone dust collector is generally 500 ~ 2000Pa. Therefore, it belongs to the medium-efficiency dust collector, and can be used for the purification of high temperature flue gas, is a widely used dust collector, more used in boiler flue gas dust removal, multi-stage dust removal and pre-dust removal. Its main disadvantage is that the removal efficiency of fine dust particles (<5μm) is low.

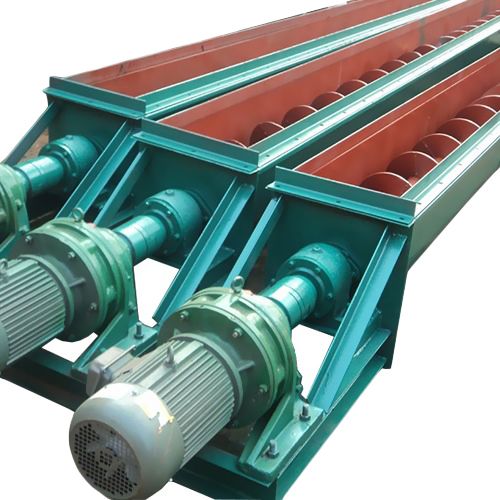

Ceramic multi-tube dust collector is a dust removal equipment composed of several parallel ceramic cyclone dust collector units (also known as ceramic cyclone). It can be composed of general ceramic cyclone dust collector unit or DC cyclone dust collector unit, these units are organically combined in a shell, with a total intake pipe, exhaust pipe and ash hopper. Ash removal of ash hopper can have many forms of automatic ash removal, because this equipment is composed of ceramic cyclone pipe, which is more wear-resistant than cast iron pipe, and the surface is smoother, with acid and alkali resistance, so it can also be wet dust removal.

Application Scope and Advantages

It is suitable for dust control of various types and combustion modes of industrial boilers and thermal power station boilers. Such as chain furnace, reciprocating furnace, boiling furnace, coal throwing furnace, pulverized coal furnace, cyclone furnace, fluidized bed furnace and so on. For other industrial dust, the dust collector can also be used to treat, but also to use the dust collector for cement and other practical value of dust recovery.

Product detail pictures:

Related Product Guide:

Well-run equipment, specialist income crew, and better after-sales services; We're also a unified major family, anyone stay with the organization value "unification, determination, tolerance" for Top Suppliers Multi Cyclone Dust Collector Working Principle - Cyclone Dust Collector – Xintian , The product will supply to all over the world, such as: Sweden, Palestine, New York, Our items have national accreditation requirements for qualified, high quality goods, affordable value, was welcomed by people today all over the world. Our products will continue to enhance within the order and look forward to cooperation with you, Should really any of these products and solutions be of curiosity to you, be sure to letus know. We are likely to be content to offer you a quotation up on receipt of your detailed needs.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!