Working principle of 4-72C centrifugal fan

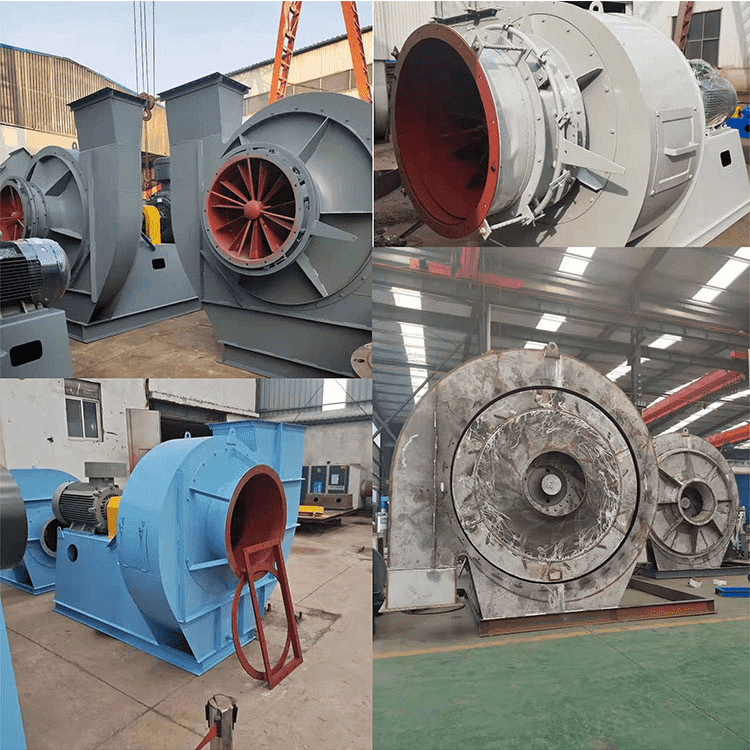

The 4-72C centrifugal fan is mainly composed of impeller, casing, coupling and shaft. Impeller is the main working part which produces wind pressure and transfers energy. The casing is mainly used to introduce and discharge gas, and change part of the kinetic energy of gas into pressure energy; Coupling is used to connect motor and fan, transfer torque; The shaft mounts and holds the impeller through the coupling with the motor.

Working principle

When the gas between the blades of 4-72C centrifugal fan rotates in the impeller, the kinetic energy (dynamic pressure head) is discharged from the periphery of the impeller by centrifugal force, and is guided by the volute shell to flow to the outlet of the fan, so that the negative pressure is formed in the impeller part, so that the external airflow flows in and replenishes, so that the fan can discharge the gas.

The motor passes the power to the fan impeller through the shaft, and the impeller rotates to transfer the energy to the air. Under the action of rotation, the air produces centrifugal force, and the blades of the air fan impeller are diffused around. At this time, the larger the fan impeller is, the greater the energy received by the air, which is the greater the fan pressure head (wind pressure). If the large impeller is cut small, the air volume will not be affected, but the wind pressure will be reduced.

4-72C centrifugal fan is mainly composed of impeller and casing. The impeller of small fan is directly mounted on the motor. Medium and large fans are connected with the motor through coupling or belt pulley. 4-72C centrifugal fan is generally a single side intake, with a single stage impeller; Large flow can be double side inlet, with two back to back impeller, also known as double suction type 4-72C centrifugal fan.

Post time: Mar-26-2022