The inclination of the dust-proof plate in the pulse bag filter should not be less than 70 degrees, which can effectively prevent the phenomenon of dust accumulation due to the too small angle between the two bucket walls. It needs to be effective on the adjacent side plates. Weld on the slide plate, which can eliminate the dust deposition.

If the pulse bag filter does not operate normally or because the humidity of the dust being processed is high, the ash bucket will be clogged with condensation. When the bucket ash is designed, the wall plate of the high-temperature filter is added with steam pipe insulation or tubular electric heating. This can effectively prevent its gray cloak material.

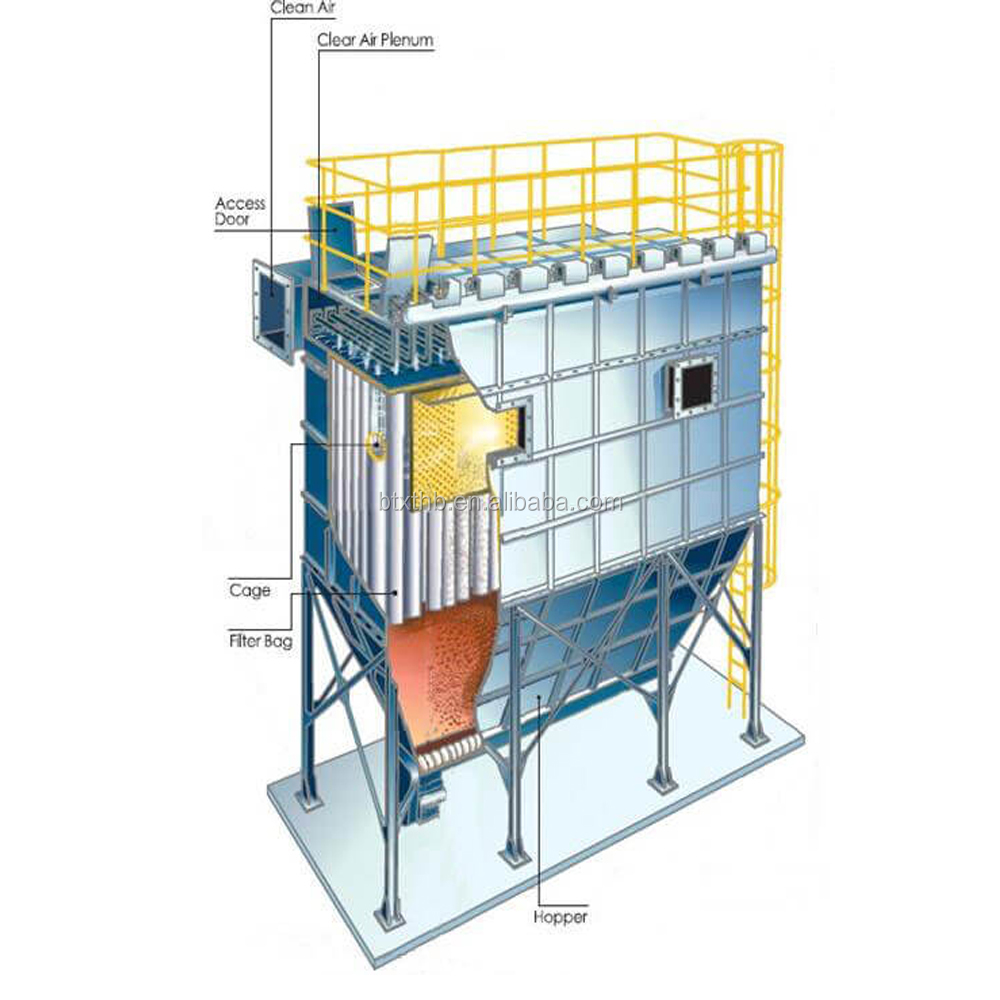

The basic structure of the pulse bag filter is composed of three parts: fan, filter and dust collector. All parts are installed in a vertical frame, steel plate shell, beautiful appearance, scientific structure, easy operation and use.

Install the bag frame of the baghouse into the baghouse. When installing, pay attention to slowly put the frame into the dust bag. If there is a large resistance, you must pull it back up a little, and then gently lower it. If the resistance is still large, repeat the operation until you can easily lay down. To prevent the frame corners from scratching the dust bag, it is strictly forbidden to make the frame hit the dust bag.

The multi-tube desulfurization and precipitator consists of two units, namely the electrostatic precipitator unit and the bag filter unit, the electric field area and the filter area are compactly arranged in a frame, the lower part is provided with an ash hopper, and the front and rear ends are provided with a horn-shaped inlet and outlet. All devices for the air flow in the box and into the box. In general, an electrostatic precipitator unit is one or two electric fields. The XST type desulfurization bath desulfurizer is equipped, and the conventional electrostatic precipitator electric field is used as the dust removal unit to remove the coarse particles of soot in the flue gas, and then the remaining fine particles are removed by cloth bags as the secondary dust collection unit.

During the removal of S02, try to remove all the ash in the ash hopper. The hopper should be kept heated throughout the shutdown.

What is more serious is that the particle size of dust particles in the dust-laden flue gas has a certain range of time distribution research. The lower air intake method will make most of the coarse particle dust with large particle size deposited in the lower part of the dust collector, and the fine particles with small particle size will be deposited in the lower part of the dust collector. deposited on the upper part of the dust collector. From the analysis of the working principle of pulse cleaning, it can be seen that the more uniform the coarse and fine particles of the dust layer adsorbed on the surface of the filter material, the better the air permeability and the cleaning effect. Obviously, the distribution of the above data is an important defect, and the longer the filter is, the defect is the greater the degree.

The pulse dust collector adopts the sub-chamber air-stop pulse jet dust cleaning technology, which overcomes the shortcomings of the conventional pulse dust collector and the sub-chamber back-flushing dust collector. It has less steel consumption, less floor space, stable and reliable operation, and good economic benefits. It is suitable for purification of dusty gas and material recovery in metallurgy, building materials, cement, machinery, chemical industry, electric power, and light industry.

Post time: Mar-02-2022