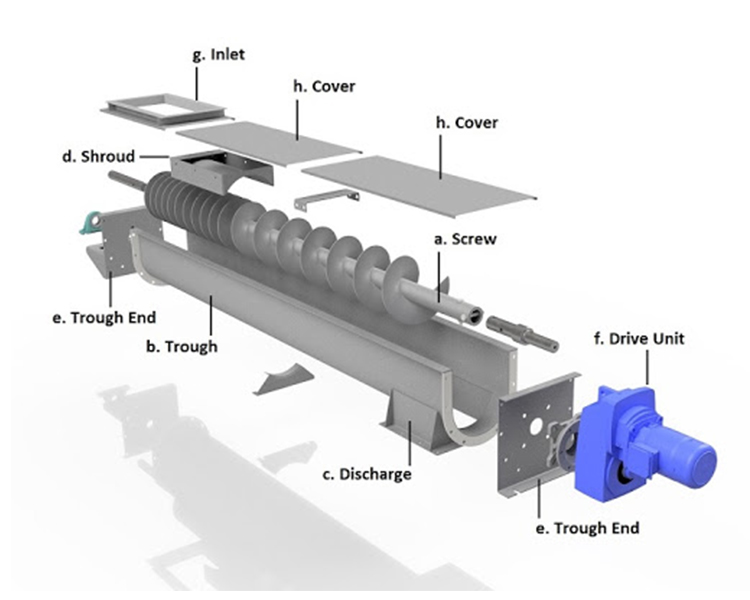

Screw conveyors are commonly known as screw augers. They are suitable for short-distance horizontal or vertical conveying of powdery, granular and small block materials. They are not suitable for conveying materials that are perishable, viscous, and easy to agglomerate. The operating environment temperature is usually -20~50℃. . The screw conveyor is usually composed of three parts: the screw conveyor body, the in and out device, and the driving device. The screw machine body is composed of three parts: head section, middle section and tail section. The screw conveyor has advanced structure, strong adaptability, low resistance, long life, convenient maintenance, and protection device.

During the application of the screw conveyor, the following requirements should be observed:

1. During the operation of the screw conveyor, the articles in the design of the conveyed articles must be complied with, and the design capability of the screw conveyor must be observed.

2. It should be noted that all kinds of personnel are not allowed to touch the moving parts of the belt conveyor, and non-professionals are not allowed to touch electrical components, control buttons, etc. at will.

3. During the operation of the screw conveyor, it is not allowed to disconnect the inverter at the rear stage. If it is determined that the maintenance needs, it must be carried out when the inverter operation is stopped, otherwise the inverter may be damaged.

4. When the screw conveyor stops, press the stop button and wait for the system to stop before cutting off the main power supply.

The powder screw conveyor can carry out horizontal, inclined and vertical conveying, and the conveying can also form a space conveying line. The conveying line of the powder screw conveyor is generally fixed. The powder screw conveyor has a large conveying capacity and a long conveying distance. It can also complete several process operations at the same time during the conveying process, and it is widely used.

Post time: Oct-20-2021