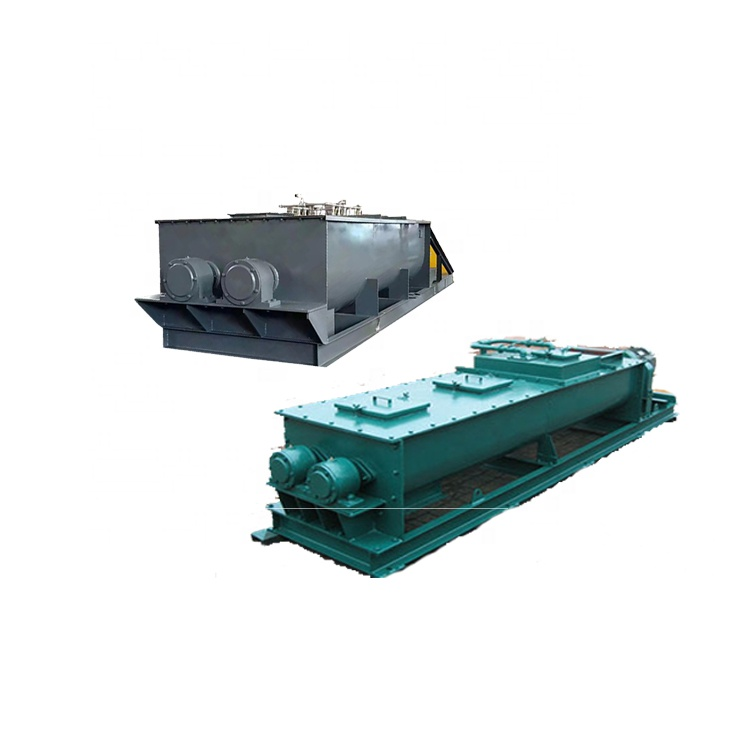

The dual-shaft humidification mixer is mainly suitable for the ash and slag unloading ash and slag system in thermal power plants or the dry ash and slag wet tree conveying system functions. Flying and environmental pollution. In the process of using the dual-shaft humidifying mixer, daily maintenance and maintenance are also very important. Today, Zhengzhou Hongxin Machinery shares a few key points with you.

Before debugging the equipment, use compressed air to clean the gear oil tank, or rinse it with water, then open the drain valve under the oil tank, close the drain valve after draining the water, and add lubricating oil. 50mm from the top surface of the fuel tank, then cover the fuel tank cover; check whether the oil cup, chain and sprocket of the reducer, mixer head and tail bearing seat are lubricated (or grease).

Before commissioning and operation of the equipment, the water supply pipeline of the water spray system of the mixer should be purged or flushed and then connected to the main water supply pipe of the main body of the machine; The debris must be cleaned up before starting the machine. The cycloid reducer and the motor are maintained according to the requirements in the product instruction manual. The lubricating oil in the gear oil tank should be replaced frequently depending on the oil quality, and the water pipes and nozzles should be checked frequently to see if they are unblocked. If the nozzle is clogged, the nozzle should be unscrewed to clean it. When cleaning, do not lose the swirl sheet in the nozzle. Be sure to tighten the nozzle when installing the nozzle. Unscrew the nozzle of which group of pipelines to clean. Open the water valve for flushing. After cleaning, screw the nozzle on, and then proceed to the next Cleaning of a set of lines.

Precautions for dust collectors in woodworking grinding workshops to solve dampness

The dust collector in the woodworking grinding workshop has a simple structure and is easy to manufacture, install and maintain. Most of them are used to remove particles above 3 μm. The parallel multi-tube cyclone dust collector also has a strong dust removal efficiency for particles of 3 μm. Introduce the precautions for the dust collector in the woodworking workshop to solve the humidity.

1. Use dust removal bags with caution: choose a smooth surface that is not easy to stick to the lake, such as glossy polyester filter material 729, needle felt dust removal bags, etc.

2. Short cleaning cycle: The cleaning cycle is short, which is conducive to timely cleaning the lime dust on the surface of the dust collector and reducing the possibility of bonding.

3. A bypass pipe is set for the lime powder bag filter: when the air is relatively humid, the dust-laden air entering the dust removal system is easy to condense. It can only be discharged into the atmosphere after the dust collector, and the above can be automatically controlled.

4. Low filtration wind speed: High filtration wind speed will force fine lime powder dust into the zigzag micro-pores inside the dust collector and block it. The binder blocks the filter holes, and the above disadvantages can be avoided by using a low filter air speed.

5. Sufficient ash cleaning and back blowing pressure: with reverse blowing ash cleaning, the lime dust entering the filter material of the dust collector can be cleaned out, and sufficient pressure is conducive to cleaning the dust in the filter material.

Post time: Apr-29-2022