New Industrial Cyclone Dust Collector With Centrifugal Fans Filter Core Components

Product Description

Cyclone dust collector is composed of intake pipe, exhaust pipe, cylinder body, cone and ash hopper. Cyclone dusters are simple in structure, easy to manufacture, install and maintain management, equipment investment and operating costs are low, has been widely used in the separation of solid and liquid particles from the air flow, or separation of solid particles from liquid. Dust Collector Bag Filter

The selection of cyclone dust collector

2. Cyclone dust collector can be used in parallel by two or four of the same diameter. The air volume it deals with is the sum of a single dust collector, and the resistance is a single resistance.In this way the diameter of each dust collector can be smaller.

3. The ash outlet of the cyclone dust collector must be kept tight so that there can be no air leakage, otherwise the dust that has settled will be taken out of the air pipe by the updraft.Dust Collector Equipment.

| Product name | Industrial Cyclone Dust Collector |

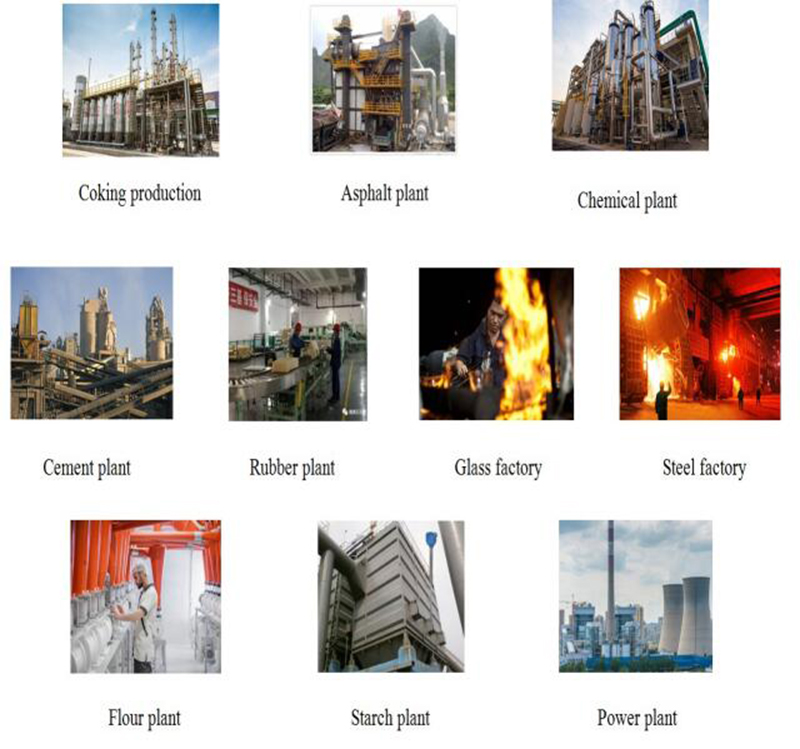

| Applicable Industries | Cyclone separators are generally used for pretreatment of dust removal at the front end of the dust removal system, and are used in conjunction with dust collectors such as filter cartridge dust collectors and bag dust collectors. The conveying medium is non-sticky, non-fiber dry dust; The flow rate of the dust removal system matches the air volume processed by the cyclone separator; The unloading method of the separator defaults to gravity unloading, and the star-shaped unloading valve can be selected for unloading” |

| Core Components | Centrifugal Fans, Filter |

| Model Number | XFT650-ZL XFT950-ZL XFT2×850-ZL XFT2×950-ZL |

| Efficiency | 70%-80% |

Advantage:

1. It is suitable for dust with high purification density and particle size greater than 5 m, but not for dust with strong adhesion;

2. No moving parts, easy to manage and maintain;

3. Small volume, simple structure and low price for the same air volume;

4. It is convenient to use multiple units in parallel when dealing with large air volume, and the efficiency resistance is not affected;

5. Can withstand high temperature of 400, if the use of special high-temperature materials, but also can withstand higher temperature;

6. After the dust collector is equipped with an abrasion resistant lining, it can be used to purify the flue gas containing highly abrasive dust.

Application

Packing & Shipping