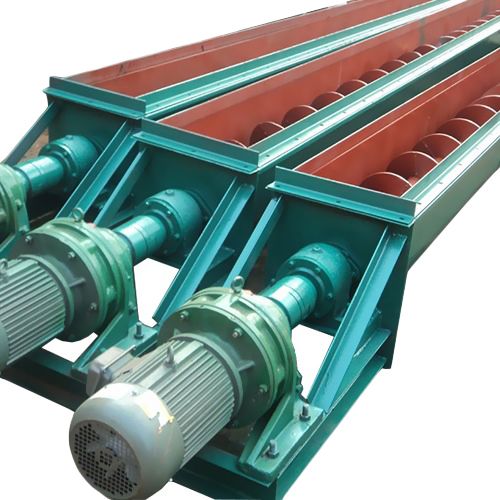

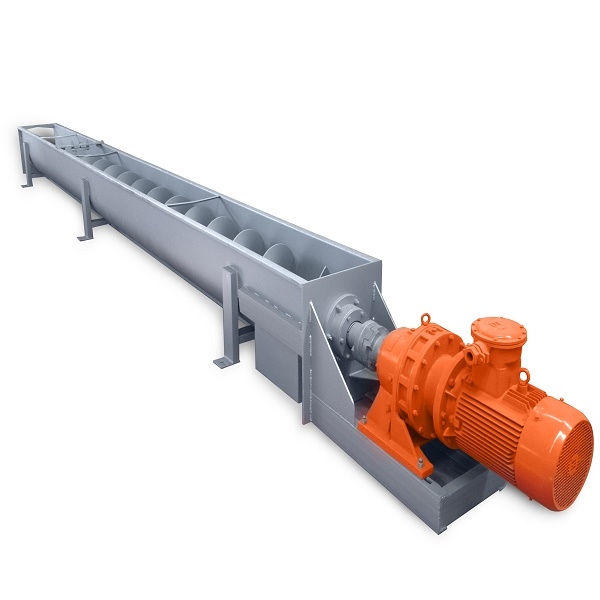

New Delivery for Tata Iron Removal Filter - Screw conveyor series – Xintian

New Delivery for Tata Iron Removal Filter - Screw conveyor series – Xintian Detail:

Working principle:

When the screw shaft rotates, the material can only move forward along the trough bottom of the conveyor under the push of the blade due to the gravity of the material and the friction force between the material and the trough wall, which is just like the translation movement of the nut that cannot be rotated along the rotating screw [3]. The movement of the material in the middle bearing depends on the thrust of the material moving forward behind. Therefore, the material transport in the conveyor, is a kind of sliding movement. In order to make the screw shaft in a more favorable tensile state, the driving device and unloading port are generally placed on the same end of the conveyor, and the feed port is placed near the tail of the other end as far as possible. The rotating spiral blade will be transported by the material, so that the material does not rotate with the screw conveyor blade force is the material’s own weight and the friction resistance of the screw conveyor casing to the material. The blade surface type according to the conveying material has the solid surface type, the belt surface type, the blade surface type and so on. The screw shaft of the screw conveyor in the direction of material movement terminal thrust bearing with material to the axial reaction force of the screw, in the captain is longer, should be added in the middle of the hanging bearing.

Screw conveyor series screw conveyor is divided into horizontal screw conveyor and vertical screw conveyor from the angle of displacement direction of conveying materials. It is mainly used for horizontal conveying and vertical lifting of various loose materials, such as powder, granular and small pieces. It is not suitable for conveying deteriorative, viscous, caking or high temperature, pressure-resistant and relatively high. Special materials with high corrosiveness. Screw conveyor is widely used in various industries, such as building materials, chemical industry, power, metallurgy, coal mine, grain and other industries. For example, coal mine, ash, slag, cement, grain, etc., the material temperature is less than 200 C

LS series screw conveyor technical parameters:

| Technical dataModel Specification |

Helical Diameter mm |

Pitch |

Speed r/min |

Standard Volume Conveyance |

Speed r/min |

Standard Volume Conveyance |

Speed r/min |

Standard Volume Conveyance |

Speed r/min |

Standard Volume Conveyance |

|||||||||

|

lv(m³/h) |

lv(m³/h) |

lv(m³/h) |

lv(m³/h) |

||||||||||||||||

|

n |

Diameter |

n |

Diameter |

n |

Diameter |

n |

Diameter |

||||||||||||

|

0.45 |

0.33 |

0.15 |

0.45 |

0.33 |

0.15 |

0.45 |

0.33 |

0.15 |

0.45 |

0.33 |

0.15 |

||||||||

|

Medium-sized |

LS200 |

200 |

200 |

100 |

16.9 |

12.4 |

5.6 |

80 |

13.5 |

9.9 |

4.5 |

63 |

10.7 |

7.8 |

3.6 |

50 |

8.5 |

6.2 |

2.8 |

|

LS250 |

250 |

250 |

90 |

29.7 |

21.8 |

9.9 |

71 |

23.5 |

17.2 |

7.8 |

56 |

18.5 |

13.6 |

6.2 |

45 |

14.9 |

10.9 |

5 |

|

|

LS315 |

315 |

315 |

80 |

52.9 |

38.8 |

17.6 |

63 |

41.6 |

30.5 |

13.9 |

50 |

33.1 |

24.2 |

11 |

40 |

26.4 |

19.4 |

8.8 |

|

|

LS400 |

400 |

355 |

71 |

85.3 |

62.5 |

28.4 |

56 |

67.3 |

49.3 |

22.4 |

45 |

54.1 |

39.6 |

18 |

36 |

43.2 |

31.7 |

14.4 |

|

|

Large |

LS500 |

500 |

400 |

63 |

133.2 |

97.7 |

44.4 |

50 |

105.8 |

77.6 |

35.3 |

40 |

84.6 |

62 |

28.2 |

32 |

67.7 |

49.6 |

22.6 |

|

LS630 |

630 |

450 |

50 |

188.9 |

138.5 |

63 |

40 |

151.1 |

111 |

50.4 |

32 |

120.9 |

88.6 |

40.3 |

25 |

94.4 |

69.3 |

31.5 |

|

|

Oversize |

LS800 |

800 |

500 |

40 |

270.7 |

198.5 |

90.2 |

32 |

216.6 |

159 |

72.2 |

25 |

169.2 |

124.1 |

54.4 |

20 |

135.4 |

99.3 |

45.1 |

|

LS1000 |

1000 |

560 |

32 |

379 |

277.9 |

126 |

25 |

296.1 |

217 |

98.7 |

20 |

236.9 |

173.7 |

79 |

16 |

189.5 |

139 |

63.2 |

|

|

LS1250 |

1250 |

630 |

25 |

520.5 |

381.5 |

174 |

20 |

416.4 |

305 |

139 |

16 |

333.1 |

244.3 |

111 |

13 |

270.7 |

198.5 |

90.2 |

|

Product detail pictures:

Related Product Guide:

"Quality initial, Honesty as base, Sincere support and mutual profit" is our idea, so as to build repeatedly and pursue the excellence for New Delivery for Tata Iron Removal Filter - Screw conveyor series – Xintian , The product will supply to all over the world, such as: Dubai, Uruguay, kazakhstan, We strongly believe that technology and service is our base today and quality will create our reliable walls of future. Only we have better and better quality , could we achieve our customers and ourselves, too. Welcome customers all over the word to contact us for getting further business and reliable relationships. We are always here working for your demands whenever you need.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.