Factory wholesale Jet Pulse Filter - Fiberglass Needle-Punched Filter Felt Bag – Xintian

Factory wholesale Jet Pulse Filter - Fiberglass Needle-Punched Filter Felt Bag – Xintian Detail:

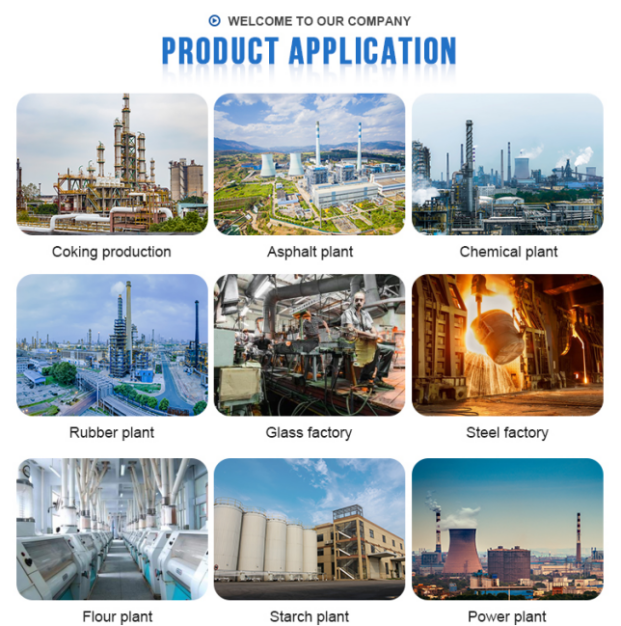

It has the advantages of high temperature resistance, corrosion resistance, dimensional stability, minimal elongation and shrinkage, high strength. And the tapetum fiber bears single fiber, three-dimensional micro-porous structure, high porosity and low resistance to gas filtration. It is a kind of high-speed and highefficiency high-temperature filtering material. It is widely used in high temperature flue gas filtration of industrial kilns such as chemical industry, iron and steel, smelting, carbon black, power generation, cement, etc.

Weight: 800g/ m²

Material: Fiberglass

Thickness: 1.8mm

Permeability: 10 m³/ m²· min

Radial control force: > 1 SOON/5 x 20cm Latitudinal control force: > 1 SOON/5 x 20cm Radial control force: < 10%

Latitudinal control force: <10%

Usage temperature: ≤ 280°C

Post-treatment: Teflon treatment

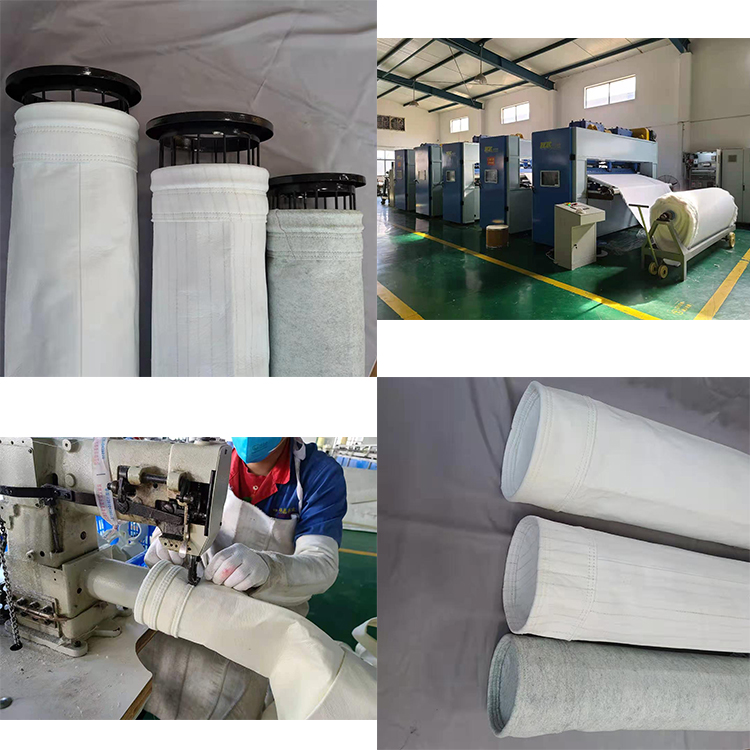

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, trust the first and management the advanced" for Factory wholesale Jet Pulse Filter - Fiberglass Needle-Punched Filter Felt Bag – Xintian , The product will supply to all over the world, such as: Gabon, Rio de Janeiro, Munich, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!