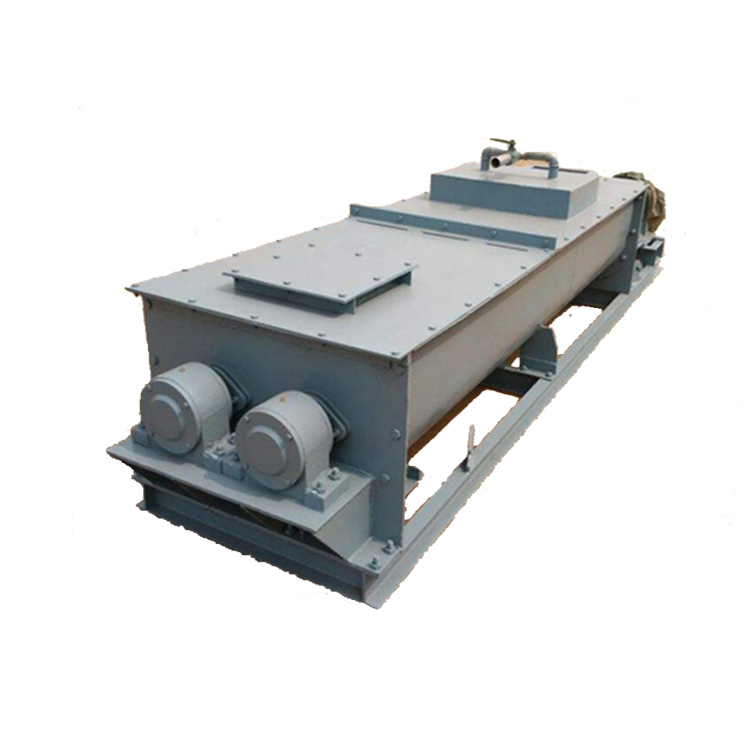

Factory wholesale Industrial Dust Removal - Filter Cartridge Dust Collector Equipment – Xintian

Factory wholesale Industrial Dust Removal - Filter Cartridge Dust Collector Equipment – Xintian Detail:

Pulse filter cartridge dust collector is mainly used in the centralized dust removal system of large factories, with large air volume treatment, small area, suitable for the whole workshop of large factories centralized dust removal, and all the dust from grinding, welding, sand cleaning, mixing, stirring, screening and other processes can be centralized treatment .

This series of filter cartridge dust collector is generally arranged outdoors and adopts oblique plug filter cartridge structure, which is convenient for maintenance and replacement of filter cartridge. The filter cartridge mostly adopts double filter cartridge combination structure, which can filter 0.2 µ m smoke dust, with filtration efficiency > 99.9%, and long service life .

It is suitable for flue gas treatment and dust removal system in industry, iron making plant, food factory, rubber factory, pharmaceutical factory, steelmaking plant, ferroalloy plant, refractory plant, foundry plant, power plant and some chemical industry and so on.

Advantages of filter cartridge dust collector:

1, The rigid filter material is evenly distributed in folding type to form the filter cartridge, which makes it have the smallest volume and the maximum filtration area effect

2, In the outer layer of the ordinary filter material, a layer of ultra-fine fiber layer is covered, so that the filtration effect has been essentially improved. The filtered dust only stays in the appearance of the ultra-fine fiber layer of filter material, so the filtration resistance is greatly reduced, and the power consumption is saved by more than 30%, and the energy saving effect is remarkable, and also the ash cleaning is very thorough. At the same time, it also solves all kinds of problems, such as ultra-fine dust, fiber dust difficult to deal with and so on

3, Selected PTFE coated filter material is suitable for wet dusty gas. Because the contact angle between filter material and water 1s more than 108 degrees, the wet dust attached to the surface of filter material is not sticky and easy to blow off. Therefore, the problem of wet dust condensation adhesive is completely solved

4, The filtration efficiency of filter cartridge dust collector: The dust collection ability of ordinary filter material with particle size above 5 µ m is 99%, and that of coated filter material with particle size over 0.5 µ m is 99%

Product detail pictures:

Related Product Guide:

In an effort to finest meet up with client's requirements, all of our operations are strictly performed in line with our motto "High High quality, Competitive Rate, Fast Service" for Factory wholesale Industrial Dust Removal - Filter Cartridge Dust Collector Equipment – Xintian , The product will supply to all over the world, such as: Uzbekistan, Colombia, Berlin, Our solutions are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we now have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.