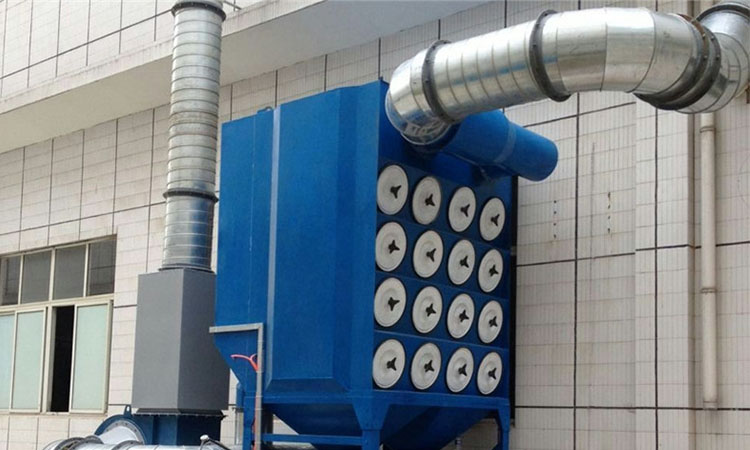

Explosion Proof Flour Cartridge Dust Collector

Introduction:

The filter cartridge dust collector consists of a filter cartridge as a filter element or adopts a pulse blowing dust collector. The filter cartridge dust collector is divided into inclined insertion type and side installation type according to the installation mode.Hoisting type, upper mounting type. The filter cartridge dust collector can be divided into long fiber polyester filter cartridge dust collector, composite fiber filter cartridge dust collector and antistatic filter cartridge dust collector according to the filter cartridge material.Flame retardant filter cartridge dust collector, coated filter cartridge dust collector, nano filter cartridge dust collector, etc.

Working principle:

The resistance of the filter cartridge dust collector increases with the increase of the thickness of the dust layer on the surface of the filter material. when the resistance reaches a certain specified value, dust is removed. at this time, the pulse controller controls the opening and closing of the electromagnetic pulse valve.When the pulse valve is opened, compressed air in the air bag is injected through the small holes on the injection pipe through the pulse valve to form a high-speed and high-pressure jet flow, thus forming an induced defect flow equivalent to 1 to 2 times the volume of the jet flow.Enter the filter cartridge together, causing instantaneous positive pressure in the filter cartridge and causing bulging and fretting; Dust deposited on the filter material falls off and falls into the ash hopper. dust in the ash hopper passes through the discharge valve.Continuous discharge.

Application:

Suitable for mixing operation, dusting operation, circuit board processing, bagging, metal processing, air supply, sandblasting, casting cutting, mixing, drilling, crushing, Stone carving work

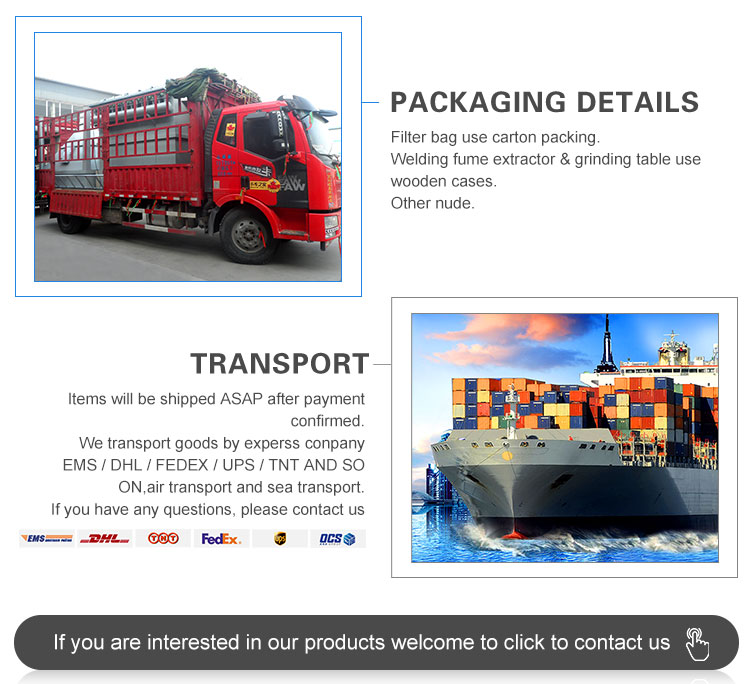

Packaging and Shipping

Packing standard:

1. Wrap moisture-proof film to prevent dampness abrasion during transportation.

2. Electronic components are packed in wooden cases or be fixed for shipment

3. When products are boxed in container, use foot bolts for fixing

4. Accessories products with carton or woven bag packaging

5. Carton packaging control products and mark shipping directions

6. Electrical products will be fixed or wrapped cotton packaging.

7. The whole device shall be fixed with wooden strips nailed at the corners of the box.