Explosion-proof cartridge dust collector

Product Description

For the collection and treatment of floating and suspended dust with a large amount of dust, an automatic discharge valve is added under the ash hopper, which has the advantages of stability and reliability, small size, good sealing performance, convenient maintenance, and long service life. For the collection and treatment of floating and suspended dust with a large amount of dust, its speed is 24r/min, and discharge valves of different powers can be selected according to different dust collection volumes to achieve a practical and economical win-win effect. The MCJC series pulse dust collector has a large-capacity and convenient dust-collecting drawer, which reduces the number of dumping and sorting. After the PTFE coating treatment, the filtration efficiency for dust above 0.3μm is more than 99%. This filtration accuracy is very good for PM2.5. The removal effect is based on the above characteristics of industrial vacuum cleaners, so it is widely used in some fields, suitable for steel, cement, furniture, ceramics, chemicals, construction, hardware, plastics, powder operations, cutting operations, grinding operations, Sandblasting operations, plexiglass processing operations and other working conditions that generate a large amount of dust. There are many types of industrial vacuum cleaners, and therefore there are many ways to use them. They can be used alone or in a complete set.

Working principle:

The resistance of the filter cartridge dust collector increases with the increase of the thickness of the dust layer on the surface of the filter material. when the resistance reaches a certain specified value, dust is removed. at this time, the pulse controller controls the opening and closing of the electromagnetic pulse valve.When the pulse valve is opened, compressed air in the air bag is injected through the small holes on the injection pipe through the pulse valve to form a high-speed and high-pressure jet flow, thus forming an induced defect flow equivalent to 1 to 2 times the volume of the jet flow.Enter the filter cartridge together, causing instantaneous positive pressure in the filter cartridge and causing bulging and fretting; Dust deposited on the filter material falls off and falls into the ash hopper. dust in the ash hopper passes through the discharge valve.Continuous discharge.

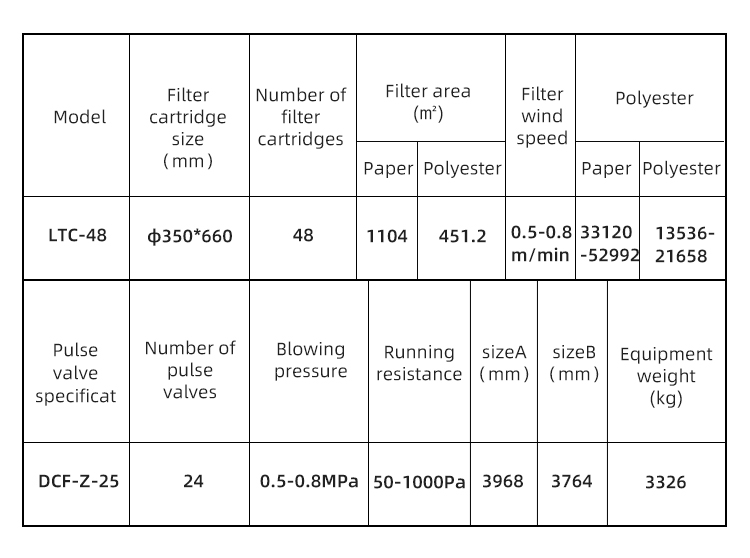

Technical Parameter

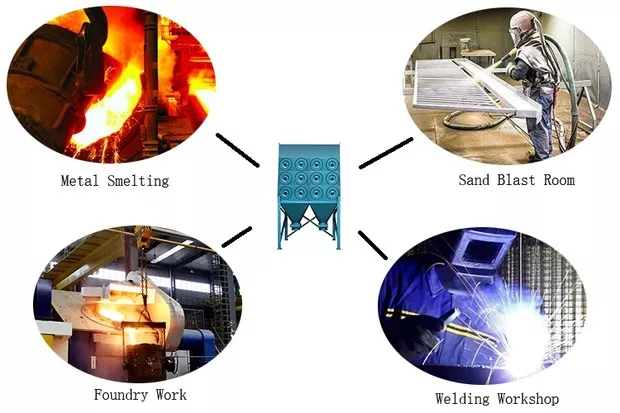

Application

Suitable for mixing operation, dusting operation, circuit board processing, bagging, metal processing, air supply, sandblasting, casting cutting, mixing, drilling, crushing, Stone carving work

Packing & Shipping