China Single pulse dust collector solenoid valve manufacturer pulse spray valve explosion-proof valve

Product Description

Right angle principle:

1. When the pulse valve is not energized, the gas enters the decompression chamber through the constant pressure pipes of the upper and lower shells and the throttle holes in them. Because the valve core blocks the pressure relief holes under the action of the spring, the gas will not be discharged. Make the pressure of the decompression chamber and the lower air chamber the same, and under the action of the spring, the diaphragm will block the blowing port, and the gas will not rush out.

2. When the pulse valve is energized, the valve core is lifted up under the action of electromagnetic force, the pressure relief hole is opened, and gas is ejected. Due to the effect of the constant pressure pipe orifice, the outflow speed of the pressure relief hole is greater than that of the pressure relief chamber. The inflow speed of the pressure pipe gas makes the pressure of the decompression chamber lower than the pressure of the lower gas chamber, and the gas in the lower gas chamber pushes up the diaphragm, opens the blowing port, and performs gas blowing.

Submerged principle: Its structure is basically the same as the right-angle pulse valve, but there is no air inlet, and the air bag is directly used as its lower air chamber. The principle is also the same.

DMF electromagnetic pulse valve is a submerged valve (also known as embedded valve), which is directly installed on the gas distribution box and has better flow characteristics. The pressure loss is reduced, which is suitable for the work occassion with lower gas source pressure.

Right Angle solenoid pulse valve is the actuator and key component of pulse jet dust cleaning device, which is mainly divided into three categories: right Angle type, submerged type and straight-through type. The solenoid pulse valve is the compressed air switch of pulse bag dust collector dust cleaning and blowing system.By pulse valve injection controller output signal control, pulse valve is connected with one end of the compressed air package, the other end is connected with the spray pipe, pulse valve back pressure chamber is connected with the control valve, pulse controller controls the control valve and pulse valve open.When the controller has no signal output, the exhaust port of the control valve is closed and the nozzle of the pulse valve is closed.When the controller sends a signal to control the vent is opened, the pulse valve back pressure gas discharge pressure reducing, outdoor produce pressure difference on both sides of diaphragm, diaphragm displacement due to the differential effect, injection pulse valve opens, the compressed air from the air bag, through the pulse valve by spray torch holes out (from the spray torch gas for a wind).Pulse valve life: five years under the condition of standard installation, correct use and reasonable maintenance.

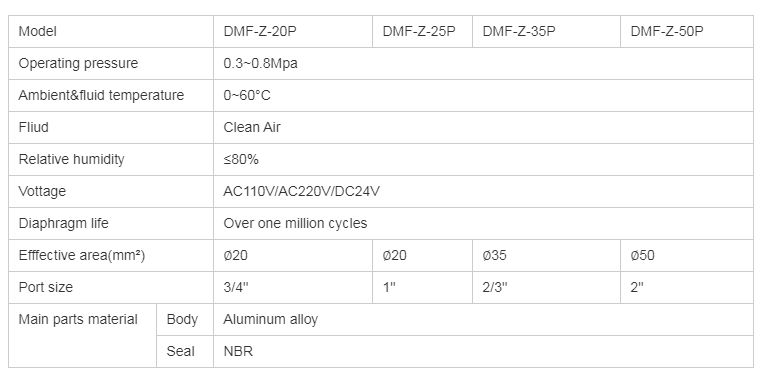

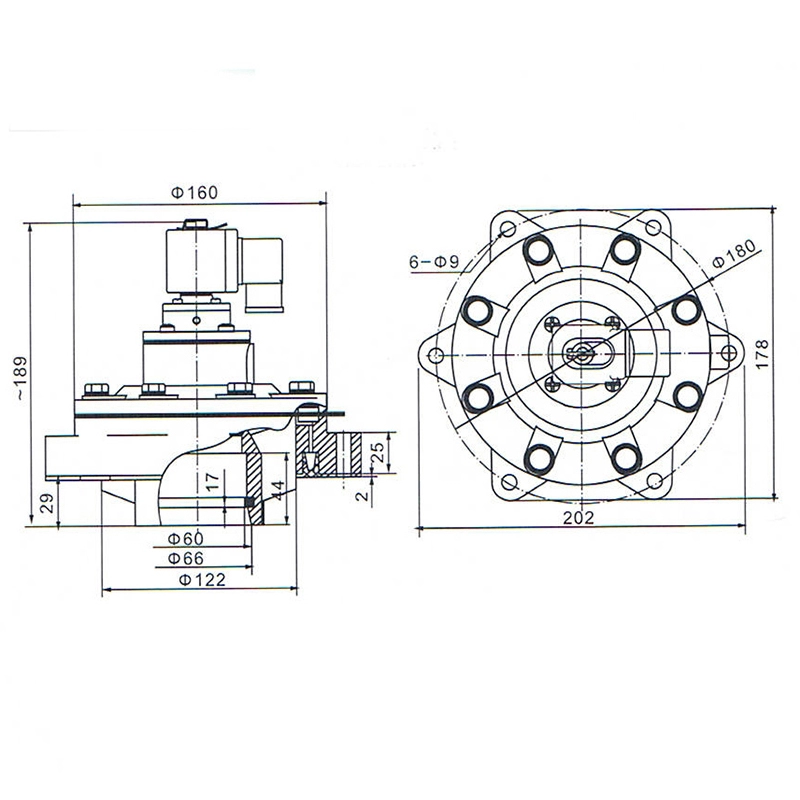

Technical Parameters of Equipment Selection:

Technical Parameters of Equipment Selection:

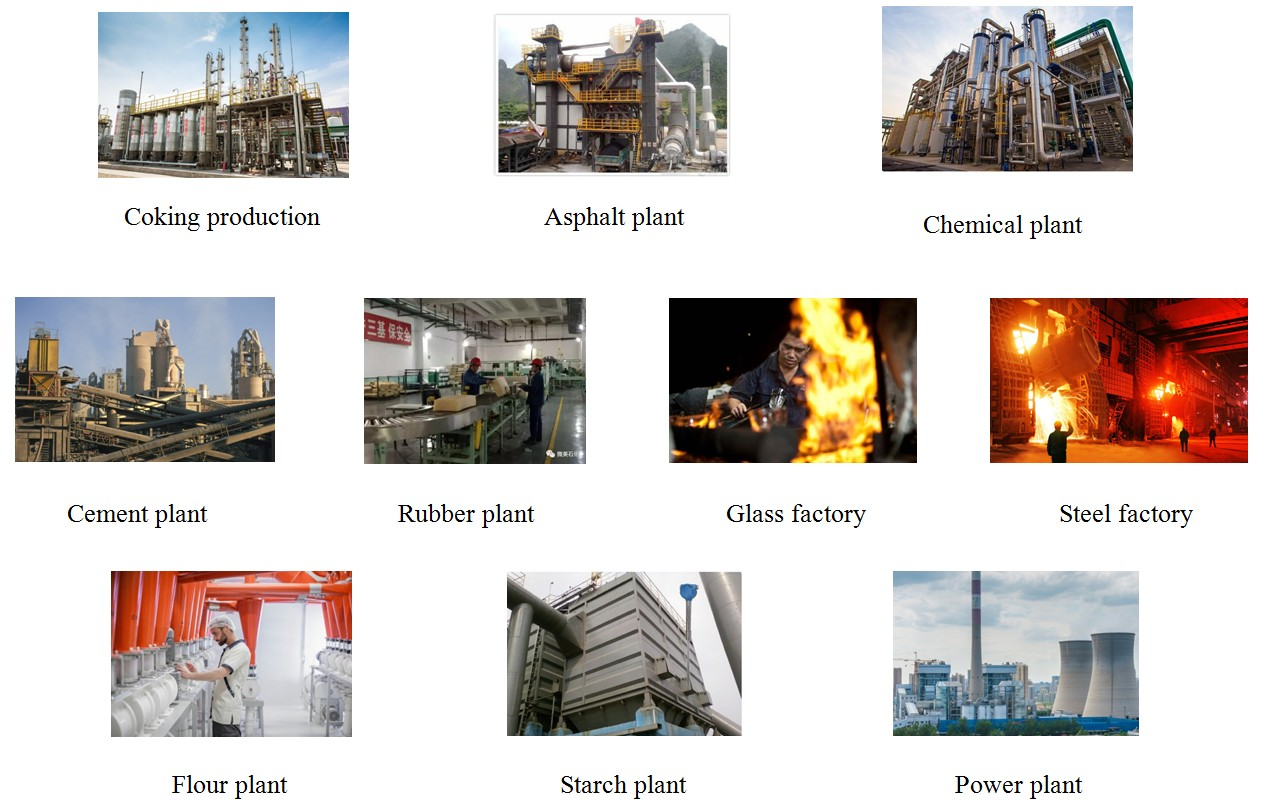

Application

Packing & Shipping