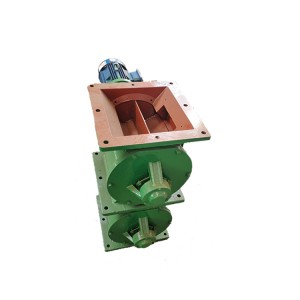

Cement factory rotary vane feeder rotary valve airlock

Product Description

The rotatry type discharge valve also known as electric discharge valve, star discharge valve, etc. It consists of motor, tooth differenced planetary gear speed reducer (X) or nylon needle cycloid speed reducer (Z) and turn the dragon tripper.

It often applied to non sticky dry fine powder or granular materials. Such as raw powder, cement, slag, coal powder, etc. Normally, they often installed in the following material library or ash bin. For block material, it can’t be used due to the block material is easy to jam their impeller.

YJD star unloader features

1, compact structure, beautiful appearance and convenient use.

2. smooth operation and low noise.

3, due to the bearing,The gear box is some distance away from the housing, and the lubrication is greatly improved for high temperature.

4. it can be designed and manufactured according to the requirements of users. 5. before the product leaves the factory,Use special grease for cycloidal reducer with pin wheel. please check and refuel regularly.

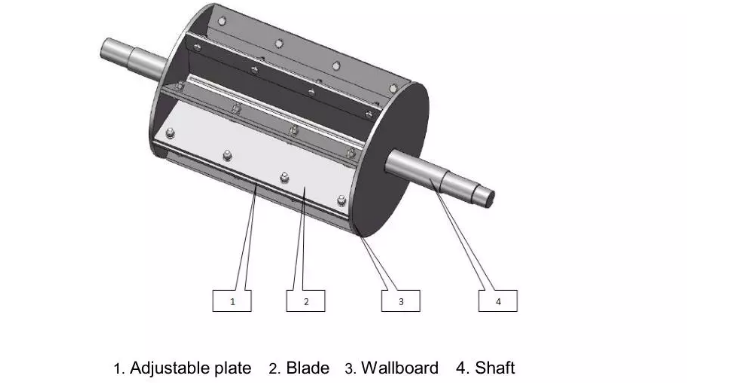

Working Principle:

Material falls onto the blades and rotates with the blades to the outlet under the airlock valve.Material can be discharged continuously.

In pneumatic conveying system,the airlock valve can lock the air and supply material continuously. The low speed of the rotor and tiny space can prevent the airflow from reverse flow,and ensure a stable air pressure and regular discharge of the material.The arilock valve acts as the material discharger in the material collecting system.

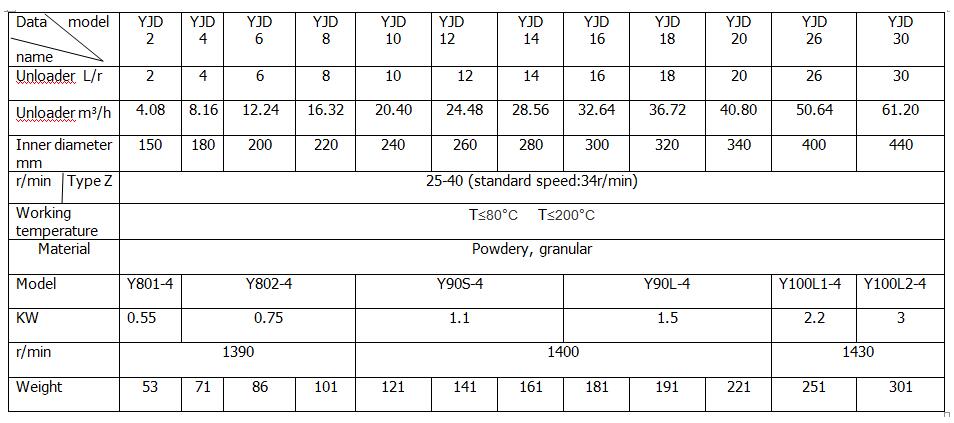

Technical parameter

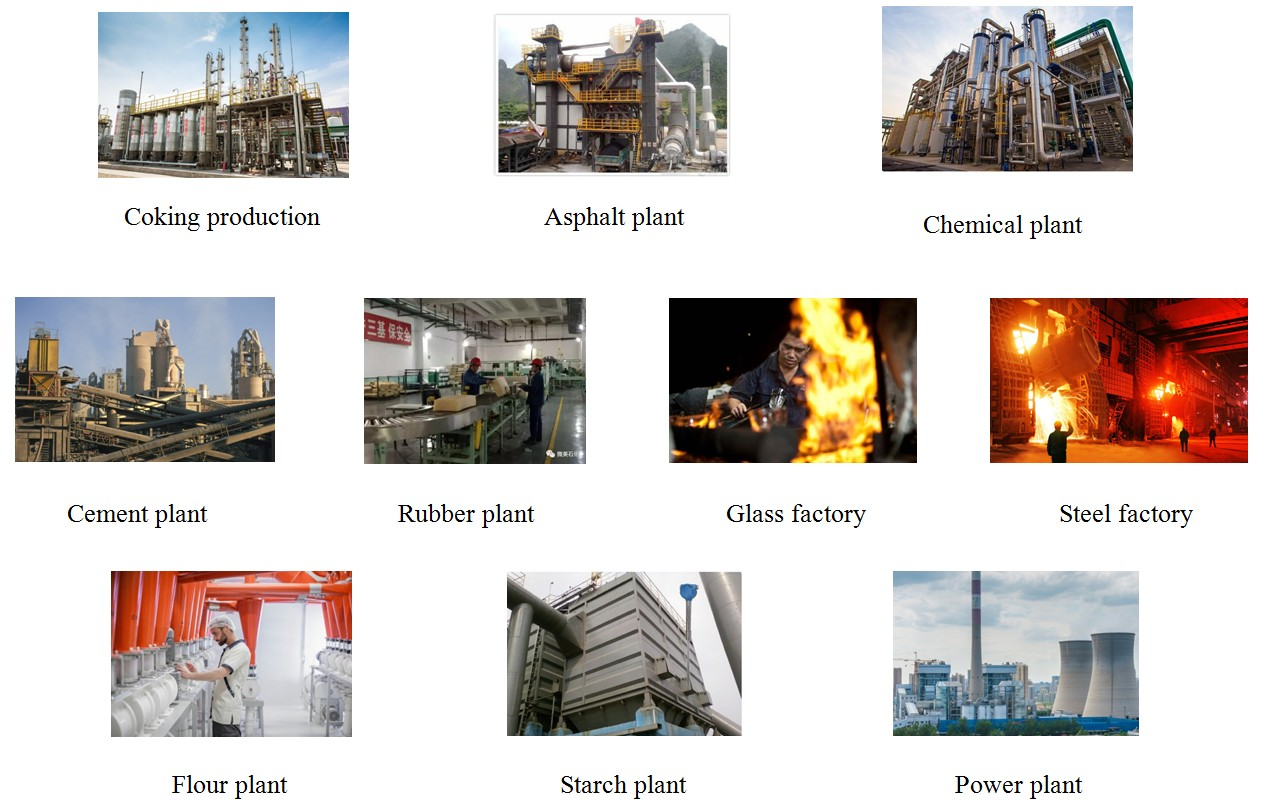

Application

Packing & Shipping