Bag House Industrial Cyclone Dust Collector for Woodworking

Product Description

Cyclone dust collector is composed of intake pipe, exhaust pipe, cylinder body, cone and ash hopper. Cyclone dusters are simple in structure, easy to manufacture, install and maintain management, equipment investment and operating costs are low, has been widely used in the separation of solid and liquid particles from the air flow, or separation of solid particles from liquid.

Working principle

As the dirty air enters the cyclone dust collector, it is forced into a swirling movement. This results in a centrifugal force acting on the dust particles suspended in the air stream. The particles, denser than the air, are forced to move outwards, towards the cyclone dust collector wall. They then fall downwards, towards the dust exit. The clean air is eventually directed towards the centre of the cyclone and leaves through the gas exit.

Product parameters

| Product name | Industrial Cyclone Dust Collector |

| Applicable Industries | Cyclone separators are generally used for pretreatment of dust removal at the front end of the dust removal system, and are used in conjunction with dust collectors such as filter cartridge dust collectors and bag dust collectors. The conveying medium is non-sticky, non-fiber dry dust; The flow rate of the dust removal system matches the air volume processed by the cyclone separator; The unloading method of the separator defaults to gravity unloading, and the star-shaped unloading valve can be selected for unloading” |

| Core Components | Centrifugal Fans, Filter |

| Model Number | XFT650-ZL XFT950-ZL XFT2×850-ZL XFT2×950-ZL |

| Efficiency | 70%-80% |

Main Features

1)Size: customized design depend on customer local environment.

2)Collect efficiency:60~70%

3)Air volume:from 1000m3/h to 1000000m3/h.

4)Handle temperature: environmental temperature to 900 degree.

5)Dust emissions:depend on dust concentration.

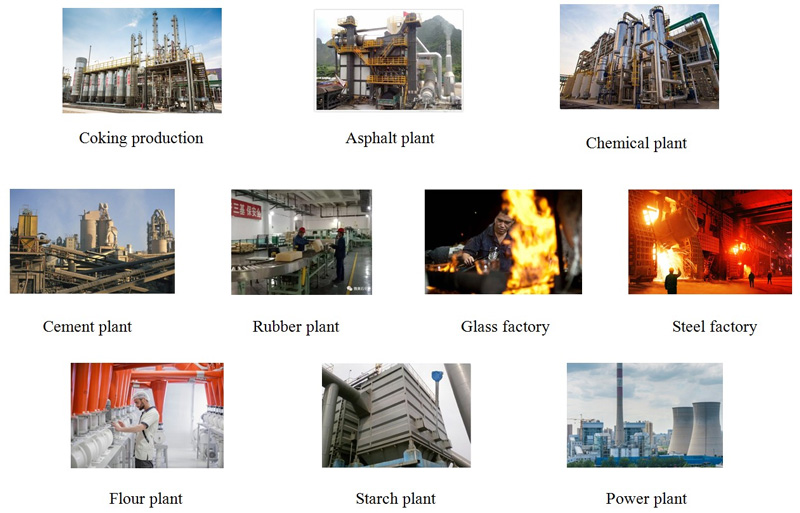

Application

Packing & Shipping