2021 new products air permeability PTFE filter bag in china factory

Product Description

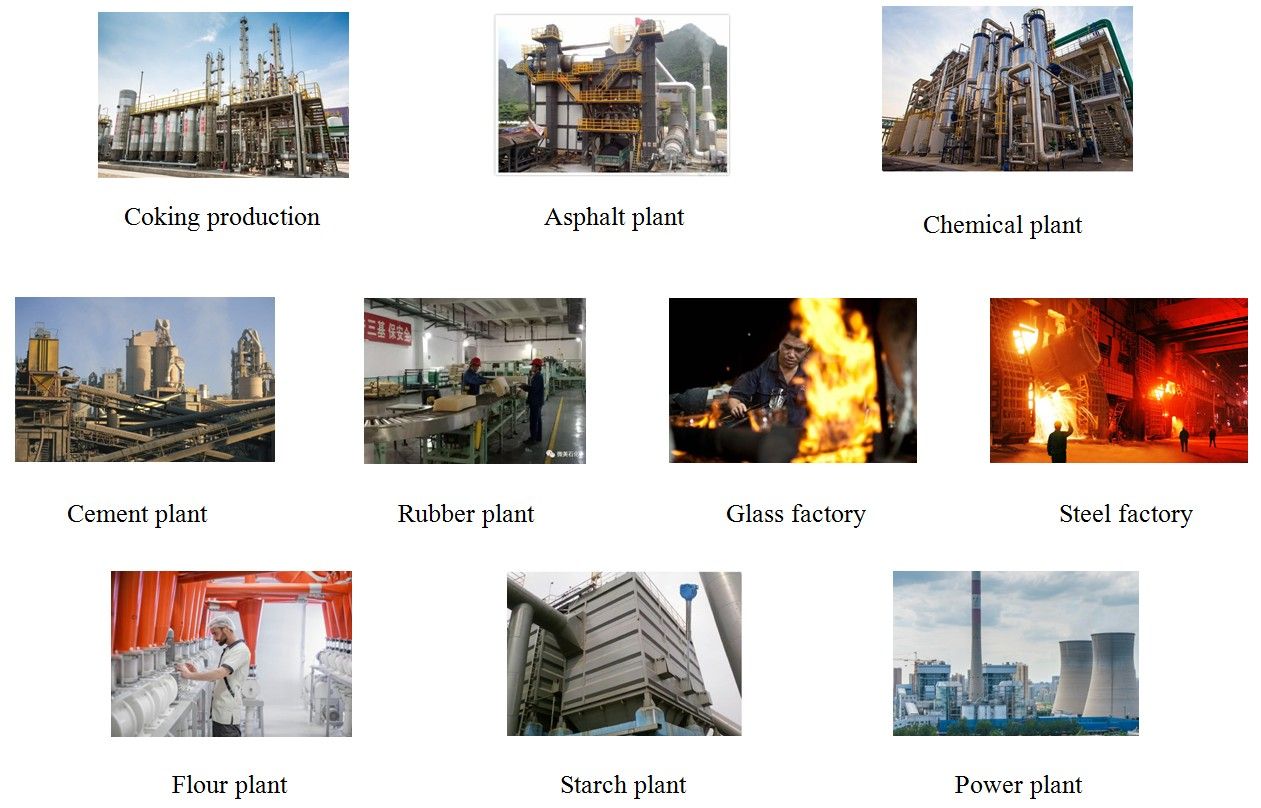

Polyester dust collector filter bag are very popular recently, most of the cement industry electrical plant asphalt plant waste water treatment workshop come to us.

PTFE performance feature

Technical Parameters of Equipment Selection:

Weight: 500g/ m²

Material: Polyester/Polyester/Polyester Antistatic Substrate Thickness: 1.8mm

Permeability: 15 m³/ m²· min

Radial control force: > 800N/5 x 20cm

Latitudinal control force: > 1200N/5 x 20cm

Radial control force: <35%

Latitudinal control force: <55%

Usage temperature:≤130°C

Post-treatment: singeing, calendering, or Teflon coating

Application and Industry

1.Asphalt – Durable construction required for abrasive, high temp environments. Hotmix or batch plants, whether natural gas, waste oil, fuel oil, etc. Replacements filters for OEMs like Astec, Gencor, Standard-Havens, etc.

2.Cement – Filters for all areas of plant: kilns baghouses, silo bin vents, nuisance dust collection, etc. Our filters exceed all EPA emissions standards (NESHAP, CMAT, MACT for portland cement, PM2.5, etc.). Replacement filters to fit ABB/Flakt, Flexkleen, FLS/Fuller, Mikropul, Norblo, Redecam, Solios and other dust collector OEMs.

3.Chemical – Filter fabrics for acidic or alkali compounds, corrosive or abrasive elements, etc. (lime, calc, fertilizer, plastics, etc.) – Special treatments and fabrics available. We can advise on the best combination for performance and cost.

4.Food Processing – The approved food-grade fabrics construction available for dust collectors used in food production, transportation and packaging such as dust collectors on milling equipment, blenders, mixers, granulators, grain elevators, storage silos and more.

5.Foundry and Metal Products – Filters for units used on arc/induction furnaces, casting operations, and precious metal reclamation. Fabrics and coatings for use in high temperature environments with need for high efficiency fume and smoke collection. Filters to fit major OEMs like Amerex, Norblo, Wheelabrator, and others.

6.Power Generation and Industrial Boilers – Our filters exceed new EPA emissions regulations for boilers and power generation (Mercury and Air Toxics, Boiler MACT, NESHAPs, etc.). We have much experience working with biomass and coal power production facilities to overcome technical challenges to meet new EPA regulations. Filter fabrics and treatments include PPS, P84, PTFE/Teflon (fabric), fiberglass, and ePTFE membrane.

7.Wood, Sand and Minerals – Often requires filters with flame resistant coatings, or constructed from nonflammable materials. We can manufacture filters to fit collectors from MAC, Murphy-Rodgers, Pneumafil, Torit, Farr and others.

Needle Felt Cloth

Application

Packing & Shipping